Our programmable stepper motor controllers are engineered to transform simple components into intelligent motion systems, making advanced automation accessible to everyone. These controllers are an ideal drives for your system and provide a reliable auto-feed function for your packaging, labeling, cutting, or assembly machine.

Auto-feed in the modern industry

Beyond simple motion, a true auto-feed function is the brain of industrial machine. It’s the ability to automatically advance material (film, paper, wire, or fabric) based on sensor inputs, timers, or complex programmed sequences. It's what turns a manual process into a seamless, high-throughput automated one.

The heart of Intelligence: powerful and programmable logic

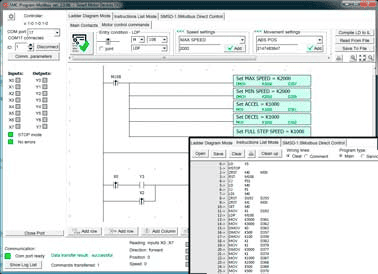

Our controllers are more than just drivers; they are compact programmable logic controllers (PLCs) dedicated to motion. Users can create sophisticated auto-feed algorithms with ease:

- Programmable I/Os: Connect limit switches, photoelectric sensors, and buttons. Trigger outputs for solenoids, knives, or indicators.

- Advanced programming: use subroutines, loops, timers, and conditional statements to build complex sequences.

- External interrupts: Implement immediate, high-priority responses to critical events for maximum safety and efficiency.

- Full motion control: Define any movement profile—speed, acceleration, deceleration, and complex multi-step sequences.

Simplify complexity: software for everyone

We believe powerful technology should be easy to use. That’s why we provide intuitive PC software that allows any user, regardless of programming expertise, to design and deploy their motion logic.

- Simple scripting: create complex auto-feed cycles with a straightforward command set.

- Easy parameter setup: Configure all motor and motion parameters in a clear, guided interface.

- Rapid deployment: Write your finished program to the controller in seconds via USB.

Seamless integration into your ecosystem

Connect and control your system your way:

- USB: For quick setup, on-the-fly adjustments, and direct PC control.

- Ethernet: For integration into factory systems and remote monitoring.

- RS-485: For robust, long-distance communication in multi-drop industrial networks.

Lower power consumption and heating

Our controllers are designed for efficiency and reliability. “Lower power consumption and heating” – it is not just a slogan, it's a result of our intelligent design. Our controllers feature advanced current management that automatically reduces motor holding current, leading to:

- Significantly less heat generation, extending the life of your motor and controller.

- Reduced energy costs for a greener and more economical operation.

- Enhanced system stability: and reliability, even in 24/7 operating environments.

Several current versions for any stepper motors

We provide a scalable solution for any task, with a range of controllers designed to power any motor in your facility:

- Small current series (current per phase up to 1.5A) for compact stepper motors: Perfect for small-scale automation, laboratory equipment, and precise dosing applications.

- Middle current series (current per phase up to 4A): the workhorse for most industrial tasks, including conveyor belts, packaging machines, and CNC auxiliaries.

- High current series (current per phase up to 8A): for high torque solutions: built to drive large stepper motors in demanding applications like heavy material handling and large-format cutting systems.