Stepper motor with integrated controller SM4247 with SMD‑1.6mini IP65

Voltage

12 - 24 VDC

Size

NEMA 17 (42 mm)

Holding torque

4.4 kgf∙cm

Control methods

STEP/DIR

Microstepping

1/1 - 1/256

Stepper motor SM4247 with integrated driver SMD‑1.6mini with protection class IP65 is designed to perform positioning tasks in an environment with a high content of microparticles. The drive is a ready to work assembly, which provides smooth running, high dynamics and precise positioning.

Technical data

Size

NEMA 17

Flange

42 mm

Protection class

IP65

Voltage

12 - 24 VDC

Holding torque

4.4 kgf∙cm

Control methods

STEP/DIR

Step angle

1.8°

Microstepping

1/1 - 1/256

Resistance per phase

1.65 Ohm

Inductance per phase

2.8 mH

Rotor inertia

68 gcm²

Weight

0.6 kg

Inputs STEP, DIR, ENABLE:

High voltage level

5 - 24 VDC

Low voltage level

0 - 1 VDC

Size

NEMA 17

Flange

42 mm

Protection class

IP65

Voltage

12 - 24 VDC

Holding torque

4.4 kgf∙cm

Control methods

STEP/DIR

Step angle

1.8°

Microstepping

1/1 - 1/256

Resistance per phase

1.65 Ohm

Inductance per phase

2.8 mH

Rotor inertia

68 gcm²

Weight

0.6 kg

Inputs STEP, DIR, ENABLE:

High voltage level

5 - 24 VDC

Low voltage level

0 - 1 VDC

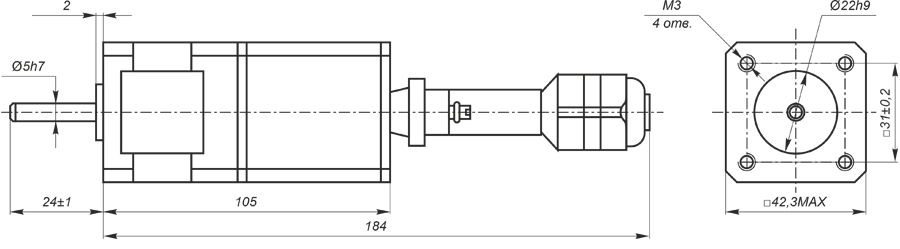

Dimensions of stepper motor SM4247 with integrated controller SMD‑1.6mini IP65

Description of stepper motor SM4247 with integrated controller SMD‑1.6mini IP65

The electric drive provides good rotation speed, high accuracy and low vibration. The drive is controlled and its parameters are adjusted by pulse signals applied to the control inputs through a waterproof connector. The control of the settings is carried out by the signals of the LED indicator.

The stepper drive provides the required speed and direction and fixation in a given position by means of logical signals STEP (impulse), DIRECTION (level) and ENABLE (level).

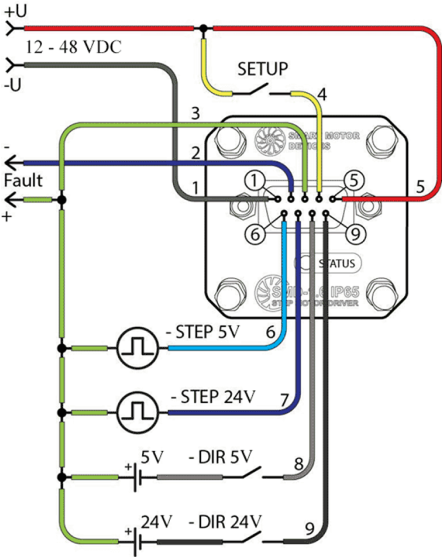

Connection of stepper motor SM4247 with integrated controller SMD‑1.6mini IP65

The built-in driver is configured by the SETUP signals applied to the contact of the driver. The duration of the SETUP signals is at least 100 ms.The time interval between signals is no more than 3 s. To facilitate the configuration of the built-in driver, it is recommended to connect the SETUP according to the connection diagram below. The driver setting parameters are displayed using a two-color LED. The number of red signals indicates the parameter number, and green indicates its value.

Connection diagram of integrated driver SMD‑1.6mini

Downloads

Get a quote

Dear guest

Thanks for your message!

We will contact you as soon as possible.

Error

Something goes wrong.

Please try later.