DC brush geared motors

Brush motors are easy to use and in common don't need any electronics to run. At once there is possibility to improve dc brush motor movement in order to adjust motion for exact application.

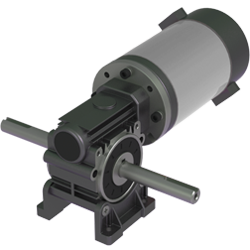

SM5946W

Brush DC gearmotor

Rated torque

30 kgf∙cm

Rated speed

80 rpm

Voltage

12 V

Gearhead

worm, 1/30

SM5946W is a DC brush motor with a worm gearhead. The motor is reversible, maintenance-free. Gearmotor is self-impeding. Supply voltage 12 VDC is suitable for a wide range of applications. 24 VDC power supply is upon a request. The standard reduction ratio is 1/30. Other ratios are on request.

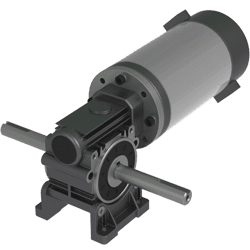

SM6551W

Brush DC gearmotor

Rated torque

78 kgf∙cm

Rated speed

54 rpm

Voltage

24 V

Gearhead

worm, 1/65

A reversible DC brush motor is equipped with a worm gearhead. The motor is maintenance-free. The worm gearbox is self-impeding, this is useful feature for some systems. Supply voltage 24 VDC is common for industrial using. We supply the geared motor reduction ratio 1/65.

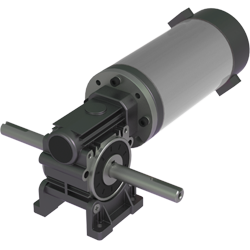

SM7152W

Brush DC gearmotor

Rated torque

104.5 kgf∙cm

Rated speed

50 rpm

Voltage

24 V

Gearhead

worm, 1/50

DC brush motor is equipped with a worm gearhead. The motor is maintenance-free. The worm gearbox is self-impeding, this is useful feature for some systems. Supply voltage 24 VDC is common for industrial using. We supply the geared motor reduction ratio 1/50.

SM7165W

Brush DC gearmotor

Rated torque

110 kgf∙cm

Rated speed

87 rpm

Voltage

24 V

Gearhead

worm, 1/30

SM7165W is a DC brush motor with worm gearhead. The motor is reversible, maintenance-free. Gearmotor is self-impeding. The standard reduction ratio is 1/30. Other ratios are on request.

SM7185W

Brush DC gearmotor

Rated torque

75 kgf∙cm

Rated speed

215 rpm

Voltage

24 V

Gearhead

worm, 1/15

SM7185W is a DC brush motor with worm gearhead. The motor is reversible, maintenance-free. Gearmotor is self-impeding. The standard reduction ratio is 1/15. Other ratios are on request.

About geared motors

DC brush motors with gearboxes, brushless motors with gearboxes, and stepper motors with gearboxes are widely used in various industries, including the space industry, medicine, and agriculture. Let's explore some examples of their applications in these fields.

In the space industry, stepper geared motors are commonly employed in satellite systems and space probes. They play a critical role in controlling the movement of antennas, solar panels, and other components. The precise motion control provided by stepper motor gearboxes ensures accurate positioning and alignment of satellite equipment, enabling efficient communication, data transmission, and scientific observations in space.

In the medical field, both DC brush motors and brushless motors with gearboxes find application in medical devices and equipment. For instance, bldc motors with gearboxes are used in robotic surgical systems, where they enable precise and controlled movement of surgical tools. This allows surgeons to perform intricate procedures with enhanced accuracy and dexterity. Additionally, brushless gear motors are utilized in medical imaging equipment, such as CT scanners and MRI machines, where they facilitate smooth and precise positioning of scanning components, resulting in high-quality diagnostic images.

In agriculture, geared motors play a crucial role in various farming applications. For example, bldc gear motors are used in automated systems for agricultural machinery, such as seeders, harvesters, and irrigation systems. The combination of brushless motors with gearboxes provides high torque and efficient power transmission, enabling reliable operation and enhanced productivity in farming processes. Additionally, stepper motor gearboxes are utilized in automated greenhouse systems for controlling ventilation, shading, and irrigation mechanisms, ensuring optimal growing conditions for plants.

The versatility of geared motors extends beyond these industries. They are also utilized in robotics, industrial automation, automotive systems, and many other applications that require precise motion control and torque amplification. In robotics, for instance, brushless gear motors are used in robotic arms and manipulators to provide accurate and controlled movements for tasks such as assembly, packaging, and material handling.

In summary, DC brush motors with gearboxes, brushless gearmotors, and stepper motors with gearboxes have diverse applications in the space industry, medicine, agriculture, and other industries. Their ability to deliver precise motion control, torque amplification, and reliable performance makes them essential for a wide range of specialized applications. By incorporating geared motors into various systems and equipment, industries can achieve improved efficiency, automation, and productivity in their operations.