Stepper motors, With encoder

Stepper motors provide precise economically effective low cost motion. The operation of stepper motors is easy to control and doesn't require feedback and expensive complicated devices.

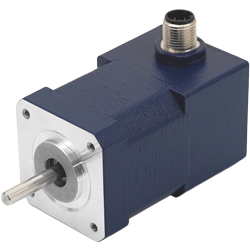

AS4118L1804‑E

Stepper motor IP65 with encoder

Size

NEMA 17

Flange

42 mm

Holding torque

5 kgf∙cm

Current per phase

1.8 A

High-torque stepper motor with M12 connector with protection class IP65 (except shaft output) in size NEMA 17 (42 mm) and 1.8° step angle (full step). Identical flange size as the standard motor ST4118, therefore electrically and mechanically interchangeable.

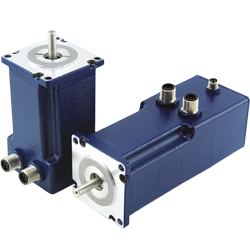

AS5918L4204‑E

Close loop stepper motor IP65 with encoder

Size

NEMA 23

Flange

56 mm

Holding torque

18.7 kgf∙cm

Current per phase

4.2 A

High-torque stepper motor with M12 connector with protection class IP65 (except shaft output) in size NEMA 23 (56 mm) and 1.8° step angle (full step). Identical flange size as the standard motor ST5918, therefore electrically and mechanically interchangeable.

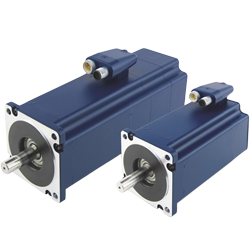

AS8918L9504‑E24

High-torque stepmotor IP65 with encoder

Size

NEMA 34

Flange

86 mm

Holding torque

93.3 kgf∙cm

Current per phase

9.5 A

High-torque stepper motor with M12 connector with protection class IP65 (except shaft output) in size NEMA 34 (86 mm) and 1.8° step angle (full step). Identical flange size as the standard motor ST8918, therefore electrically and mechanically interchangeable.

High torque stepper motors

If you're in the market for a high torque stepper motor with reliable performance, consider exploring the options available for standard NEMA stepper motor. These motors are widely used in various industries and applications that require precise motion control.

NEMA stepper motors are standardized motors that adhere to the National Electrical Manufacturers Association (NEMA) standards. These standards ensure compatibility and interchangeability among different motor manufacturers, making it easier to find compatible components and accessories. NEMA stepper motors are available in various frame sizes and configurations, allowing for versatile and flexible integration into different systems.

If you require position feedback or precise motion control, a stepper motor with encoder can be a valuable option. An encoder provides real-time feedback on the motor's position, enabling accurate positioning and control. It works by converting the motor's rotational movement into electrical signals that can be used for monitoring and closed-loop control. Stepper motors with encoders are commonly used in applications that require high accuracy and repeatability, such as CNC machines, robotics, and automated systems.

When looking for stepper motor for sale, it's essential to consider factors such as torque requirements, frame size, step angle, and operating voltage. There are various suppliers and distributors that offer stepper motors for sale, both online and in physical stores. It's recommended to research and compare different options to find the right motor that suits your specific application needs.

When buying a stepper motor, it's advisable to check the motor's specifications, including torque curves, electrical ratings, and mechanical dimensions. Understanding these specifications will help ensure that the selected motor meets your performance requirements and can be easily integrated into your system.

In summary, if you're looking to buy a stepper motor, exploring options for high torque stepper motors available in standard NEMA configurations. Additionally, if precise motion control is required, a stepper motor with an encoder can provide accurate position feedback. There are various stepper motors for sale, and understanding the specific requirements of your application will help you choose the right motor for optimal performance.