Stepper motor drivers STEP/DIR

We offer the stepper motor drivers for full line of motors. SMD drivers process STEP (Pulse) and DIR (Level) signals as motion reference. High level voltage is 5 ‑ 24 VDC which is suitable for the most signal sources.

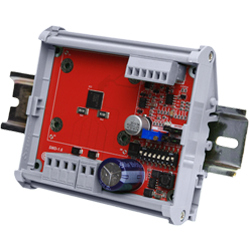

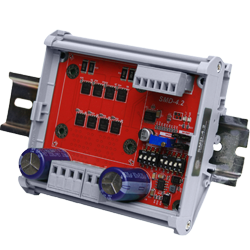

SMD‑1.6DIN

Stepper motor driver STEP/DIR

Voltage

12 – 24 VDC

Max. current per phase

0.1 - 1.6 A

Microstepping

1/1 - 1/256

Control methods

STEP/DIR

The driver is intended for small size stepper motors with current per phase up to 1.6 A. The control method is standard STEP/DIR. The driver provides smooth and exact positioning.

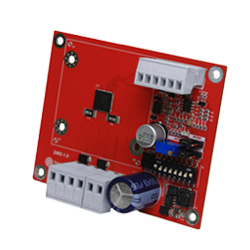

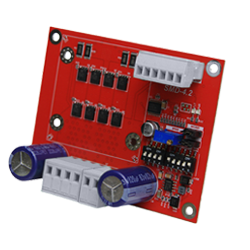

SMD‑1.6 carrier kit

Stepper motor driver

Voltage

12 – 24 VDC

Max. current per phase

0.1 - 1.6 A

Microstepping

1/1 - 1/128

Control methods

Analog input, STEP/DIR

Stepper motor driver SMD‑1.6 with DIN clamp is manufactured in an open case. A frameless version of the driver is also supplied. This compact and lightweight driver is designed for smooth movement of the stepper motor with microstepping up to 1/128, provides excellent dynamics and high motor torque.

SMD‑1.6 open frame

Stepper motor driver

Voltage

12 – 24 VDC

Max. current per phase

0.1 - 1.6 A

Microstepping

1/1 - 1/128

Control methods

Analog input, STEP/DIR

Stepper motor driver SMD‑1.6 open frame is manufactured in a frameless design, in the form of an open board with mounting holes. There is also a carrier kit version of the driver with a DIN clamp. This compact and lightweight driver is designed for smooth movement of the stepper motor with microstepping up to 1/128, provides excellent dynamics and high motor torque.

SMD‑2.8DIN

Stepper motor driver STEP/DIR

Voltage

12 – 24 VDC

Max. current per phase

1.3 - 2.8 A

Microstepping

1/1 - 1/256

Control methods

STEP/DIR

The driver is intended for small size stepper motors with current per phase up to 2.8 A. The control method is standard STEP/DIR. The driver provides smooth and exact positioning.

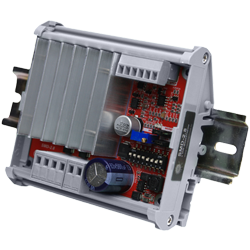

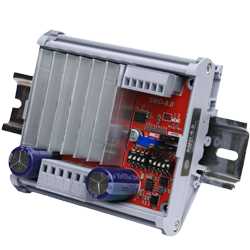

SMD‑2.8 carrier kit

Stepper motor driver

Voltage

12 – 24 VDC

Max. current per phase

1.3 - 2.8 A

Microstepping

1/1 - 1/128

Control methods

Analog input, STEP/DIR

Stepper motor driver SMD‑2.8 with DIN clamp is manufactured in an open case. A frameless version of the driver is also supplied. This compact and lightweight driver is designed for smooth movement of the stepper motor with microstepping up to 1/128, provides excellent dynamics and high motor torque.

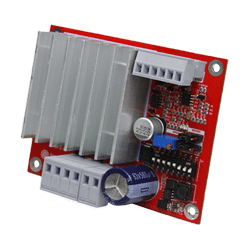

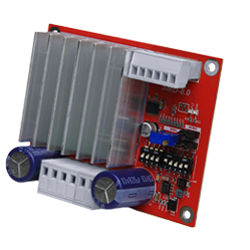

SMD‑2.8 open frame

Stepper motor driver

Voltage

12 – 24 VDC

Max. current per phase

1.3 - 2.8 A

Microstepping

1/1 - 1/128

Control methods

Analog input, STEP/DIR

Stepper motor driver SMD‑2.8 open frame is manufactured in a frameless design, in the form of an open board with mounting holes. There is also a carrier kit version of the driver with a DIN clamp. This compact and lightweight driver is designed for smooth movement of the stepper motor with microstepping up to 1/128, provides excellent dynamics and high motor torque.

SMD‑4.2DIN ver.3

Stepper motor driver STEP/DIR

Voltage

12 – 48 VDC

Max. current per phase

2.7 - 4.2 A

Microstepping

1/1 - 1/256

Control methods

Analog input, STEP/DIR

The stepper motor driver is designed to control motors with current per phase up to 4.2 A. This model provides 2 control methods: STEP/DIR positioning and analog speed control. The controller provides an excellent motor dynamics and high torque performance. Slim case and mounting the driver on a standard DIN rail makes it easy to place it in a production environment.

SMD‑4.2 carrier kit

Stepper motor driver

Voltage

12 – 48 VDC

Max. current per phase

2.7 - 4.2 А

Microstepping

1/1 - 1/256

Control methods

Analog input, STEP/DIR

Stepper motor driver SMD‑4.2 with DIN clamp is manufactured in an open case. A frameless version of the driver is also supplied. This compact and lightweight driver is designed for smooth movement of the stepper motor with microstepping up to 1/256, provides excellent dynamics and high motor torque.

SMD‑4.2 open frame

Stepper motor driver

Voltage

12 – 48 VDC

Max. current per phase

2.7 - 4.2 А

Microstepping

1/1 - 1/256

Control methods

Analog input, STEP/DIR

Stepper motor driver SMD‑4.2 open frame is manufactured in a frameless design, in the form of an open board with mounting holes. There is also a carrier kit version of the driver with a DIN clamp. This compact and lightweight driver is designed for smooth movement of the stepper motor with microstepping up to 1/256, provides excellent dynamics and high motor torque.

SMD‑8.0DIN ver.3

Stepper motor driver STEP/DIR

Voltage

12 – 48 VDC

Max. current per phase

5.0 - 8.0 A

Microstepping

1/1 - 1/256

Control methods

Analog input, STEP/DIR

The stepper motor driver is designed to control motors with current per phase up to 8.0 A. This model provides 2 control methods: STEP/DIR positioning and analog speed control. The controller provides an excellent motor dynamics and high torque performance. Slim case and mounting the driver on a standard DIN rail makes it easy to place it in a production environment.

SMD‑8.0 carrier kit

Stepper motor driver

Voltage

12 – 48 VDC

Max. current per phase

5.0 - 8.0 А

Microstepping

1/1 - 1/256

Control methods

Analog input, STEP/DIR

Stepper motor driver SMD‑8.0 with DIN clamp is manufactured in an open case. A frameless version of the driver is also supplied. This compact and lightweight driver is designed for smooth movement of the stepper motor with microstepping up to 1/256, provides excellent dynamics and high motor torque.

SMD‑8.0 open frame

Stepper motor driver

Voltage

12 – 48 VDC

Max. current per phase

5.0 - 8.0 А

Microstepping

1/1 - 1/256

Control methods

Analog input, STEP/DIR

Stepper motor driver SMD‑8.0 open frame is manufactured in a frameless design, in the form of an open board with mounting holes. There is also a carrier kit version of the driver with a DIN clamp. This compact and lightweight driver is designed for smooth movement of the stepper motor with microstepping up to 1/256, provides excellent dynamics and high motor torque.

SMD‑4.2HV

Stepper motor driver STEP/DIR

Power supply

220 VAC

Max. current per phase

1.2 - 4.2 A

Microstepping

1/1 - 1/16

Control methods

STEP/DIR

SMD‑4.2HV is a high voltage stepper driver, designed by our company for middle sizes applications. Driver are suitable for middle current stepper motors that can be used, for example, in CNC machines for wood and plastic processing. SMD‑4.2HV is designed as a circuit plate with electronics elements, installed on a heatsink plate and covered with a metal case.

About stepper motor drivers

When it comes to controlling stepper motors, there are different options available, including programmable controllers and drivers. Each has its own advantages and features that cater to specific needs and requirements.

Stepper drives or drivers are commonly used to control stepper motors by providing the necessary electrical signals to move the motor in discrete steps. They typically operate based on the STEP and DIR signals. The STEP signal determines the step size and frequency, while the DIR signal controls the motor's direction of rotation. Stepper drivers are known for their simplicity and ease of use.

On the other hand, programmable controllers for stepper motors offer more advanced and flexible control capabilities. These controllers can be programmed to control motor speed generate precise motion profiles, including acceleration and deceleration. They allow for customized control parameters, making them suitable for applications that require specific motion control requirements.

One popular feature available in stepper motor controllers is microstepping. Microstepping allows for smoother and more precise motion control by dividing each step into smaller increments. This results in finer resolution and reduced vibrations compared to traditional full-step or half-step control methods. Microstepping is achieved by controlling the current levels in the motor windings, enabling smoother and more accurate positioning. Microstepping drivers STEP and DIR also commonly used.

Silent stepper driver is specifically designed to minimize noise and vibrations during motor operation. They utilize advanced control algorithms and current regulation techniques to reduce audible noise and resonance effects. Silent stepper drivers are particularly useful in applications where quiet operation is essential, such as in home appliances, medical devices, or audio equipment.

Controlling the speed of a stepper motor is a critical aspect of its operation. Both stepper drive and controller offer options for controlling motor speed. By adjusting the frequency of the STEP signals, the speed of the motor can be controlled. Higher frequencies result in faster motor rotation, while lower frequencies result in slower rotation. Additionally, programmable controllers allow for more precise control over acceleration and deceleration, enabling smoother speed changes.

Befor you buy a step motor driver or controller, it's essential to consider the specific requirements of the application. Factors such as the motor's voltage and current ratings, the desired resolution and accuracy, and the necessary control features should be taken into account. There are various options available in the market, and buyers can find stepper drivers or controllers suitable for their needs.

In conclusion, stepper drives and programmable controllers offer different levels of control and flexibility for stepper motor applications. Stepper drives provide basic step and direction control, while programmable controllers offer advanced features such as microstepping, silent operation, and precise speed control. The choice between a motor driver for stepper motor or a programmable controller depends on the specific needs and complexity of the application. Understanding the features and capabilities of each option is crucial for selecting the appropriate motor driver or controller for optimal performance.